Hastelloy C276 flanges are a unique type of equipment, distinguished by their remarkable material composition and superior properties. Composed of a super alloy known as Hastelloy C276, these flanges exhibit unusual durability and resistance in challenging conditions.

Hastelloy C276 is an alloy that stands out because of its distinctive blend of elements: nickel, molybdenum, and chromium primarily, with traces of iron, tungsten, cobalt, and other elements. This blend gives the Hastelloy C276 remarkable characteristics, extending these qualities to the flanges crafted from it.

Specifications Of Hastelloy C276 Flanges

| Standards | ANSI/ASME B16.5, EN Flanges, BS 10, B16.47 Series A & B, EN-1092, ASME Flanges, BS Flanges, B16.48, DIN, DIN Flanges, GOST Flanges, ANSI Flanges, BS4504. |

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Production technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Small Tongue, Raised Face (RF), Lap-Joint Face (LJF), Small Male-Female (SMF), Flat Face (FF), Large Tongue & Groove, Large Male-Female (LMF). |

| Application | Gas, Power, Chemical, Metallurgy, Petroleum, Shipbuilding, Construction etc. |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

ASTM B564 Hastelloy C276 Chemical Composition

Hastelloy C276 flange is a nickel-molybdenum-chromium alloy. The presence of molybdenum gives the alloy excellent resistance to reducing acid corrosion, while the chromium element helps to improve the alloy’s oxidation resistance and corrosion resistance, especially in oxidizing environments.

| CHEMICAL | LIMITS | Ni | Fe | Mn | C | Si | S | Cr | Mo | P | W | Co | V |

| Hastelloy C276 | MIN | Balance | 4 | 14.5 | 15 | 3 | |||||||

| MAX | 7 | 1 | 0.01 | 0.08 | 0.03 | 16.5 | 17 | 0.04 | 4.5 | 2.5 | 0.35 |

ASTM B564 Hastelloy C276 Mechanical Properties

Hastelloy C276 flanges has good strength and toughness. Its mechanical properties such as yield strength and tensile strength can meet the requirements of various harsh engineering conditions.

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

Equivalent Grades of Hastelloy C276 Flanges

| STANDARD | EN | UNS | WERKSTOFF NR. | JIS | GOST | OR |

| Hastelloy C276 | NiMo16Cr15W | N10276 | 2.4819 | NW 0276 | ХН65МВУ | ЭП760 |

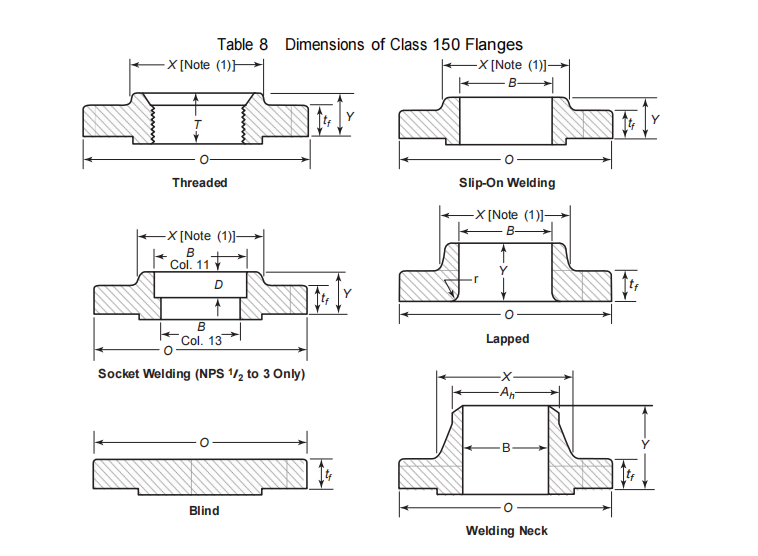

Hastelloy C276 Flanges Dimension

| Nominal Pipe Size, NPS |

O | [Notes (2)-(4)] | Lap Joint, tf |

X | [Note (5)] | Length Through Hub | [Note (6)] | Bore | [Note (7)] | r | D | |||

| Threaded/ Slip-on/ Socket Welding, Y |

Lapped, Y |

Welding Neck, Y |

Minimum Slip-on/ Socket Welding, B |

Minimum Lapped, B |

||||||||||

| 1/2 | 90 | 9.6 | 11.2 | 30 | 21.3 | 14 | 16 | 46 | 16 | 22.2 | 22.9 | 15.8 | 3 | 10 |

| 3/4 | 100 | 11.2 | 12.7 | 38 | 26.7 | 14 | 16 | 51 | 16 | 27.7 | 28.2 | 20.9 | 3 | 11 |

| 1 | 110 | 12.7 | 14.3 | 49 | 33.4 | 16 | 17 | 54 | 17 | 34.5 | 34.9 | 26.6 | 3 | 13 |

| 1 1/4 | 115 | 14.3 | 15.9 | 59 | 42.2 | 19 | 21 | 56 | 21 | 43.2 | 43.7 | 35.1 | 5 | 14 |

| 1 1/2 | 125 | 15.9 | 17.5 | 65 | 48.3 | 21 | 22 | 60 | 22 | 49.5 | 50.0 | 40.9 | 6 | 16 |

| 2 | 150 | 17.5 | 19.1 | 78 | 60.3 | 24 | 25 | 62 | 25 | 61.9 | 62.5 | 52.5 | 8 | 17 |

| 2 1/2 | 180 | 20.7 | 22.3 | 90 | 73.0 | 27 | 29 | 68 | 29 | 74.6 | 75.4 | 62.7 | 8 | 19 |

| 3 | 190 | 22.3 | 23.9 | 108 | 88.9 | 29 | 30 | 68 | 30 | 90.7 | 91.4 | 77.9 | 10 | 21 |

| 3 1/2 | 215 | 22.3 | 23.9 | 122 | 101.6 | 30 | 32 | 70 | 32 | 103.4 | 104.1 | 90.1 | 10 | |

| 4 | 230 | 22.3 | 23.9 | 135 | 114.3 | 32 | 33 | 75 | 33 | 116.1 | 116.8 | 102.3 | 11 | |

| 5 | 255 | 22.3 | 23.9 | 164 | 141.3 | 35 | 36 | 87 | 36 | 143.8 | 144.4 | 128.2 | 11 | |

| 6 | 280 | 23.9 | 25.4 | 192 | 168.3 | 38 | 40 | 87 | 40 | 170.7 | 171.4 | 154.1 | 13 | |

| 8 | 345 | 27.0 | 28.6 | 246 | 219.1 | 43 | 44 | 100 | 44 | 221.5 | 222.2 | 202.7 | 13 | |

| 10 | 405 | 28.6 | 30.2 | 305 | 273.0 | 48 | 49 | 100 | 49 | 276.2 | 277.4 | 254.6 | 13 | |

| 12 | 485 | 30.2 | 31.8 | 365 | 323.8 | 54 | 56 | 113 | 56 | 327.0 | 328.2 | 304.8 | 13 | |

| 14 | 535 | 33.4 | 35.0 | 400 | 355.6 | 56 | 57 | 125 | 57 | 359.2 | 360.2 | Note(8) | 13 | |

| 16 | 595 | 35.0 | 36.6 | 457 | 406.4 | 62 | 64 | 125 | 64 | 410.5 | 411.2 | Note(8) | 13 | |

| 18 | 635 | 38.1 | 39.7 | 505 | 457.0 | 67 | 68 | 138 | 68 | 461.8 | 462.3 | Note(8) | 13 | |

| 20 | 700 | 41.3 | 42.9 | 559 | 508.0 | 71 | 73 | 143 | 73 | 513.1 | 514.4 | Note(8) | 13 | |

| 24 | 815 | 46.1 | 47.7 | 663 | 610.0 | 81 | 83 | 151 | 83 | 616.0 | 616.0 | Note(8) | 13 | |

Differences between Hastelloy C22 and C276 Flange

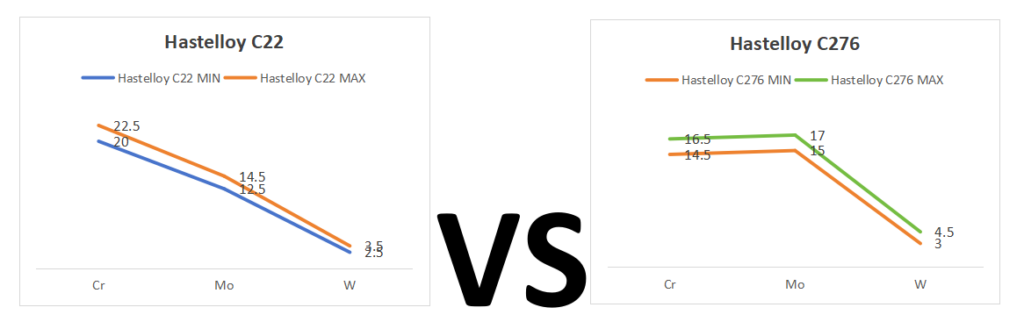

Differences in Chemical Composition

Hastelloy C276 flanges has a chromium content of 14.5 – 16.5%. Compared with Hastelloy C22 flange, the chromium content is slightly lower. The molybdenum content is 15 – 17%. The molybdenum content is slightly higher than that of C22, which may make C276 have better corrosion resistance in some reducing corrosion environments. The tungsten content is 3 – 4.5%. Its tungsten content is also slightly higher than that of C22, which has a certain impact on high temperature performance and corrosion resistance.

Different Corrosion Resistance

In a strong oxidizing acid environment, due to its higher chromium content, C22 flange can form a more stable chromium oxide protective film and show better corrosion resistance.

In some complex environments containing a mixture of oxidizing and reducing media, Hastelloy C276 flange has better comprehensive corrosion resistance.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....